Mining Separation Sawtooth WaveJig Machine

The sawtooth wave jig is a highly efficient, energy-saving, and environmentally friendly mineral processing device characterized by its compact footprint and user-friendly operation It delivers excellent performance in processing various metallic and non

Sawtooth Wave Jig Description

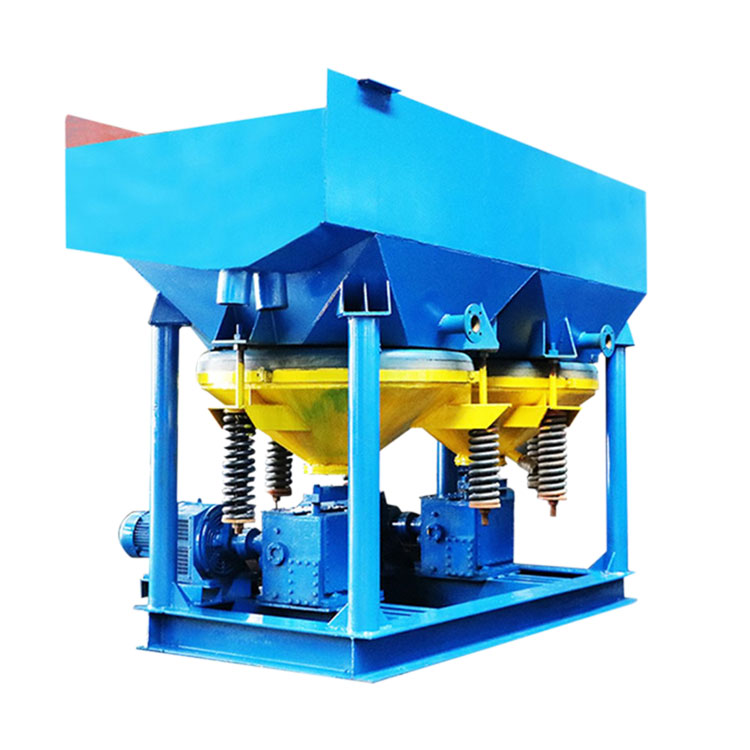

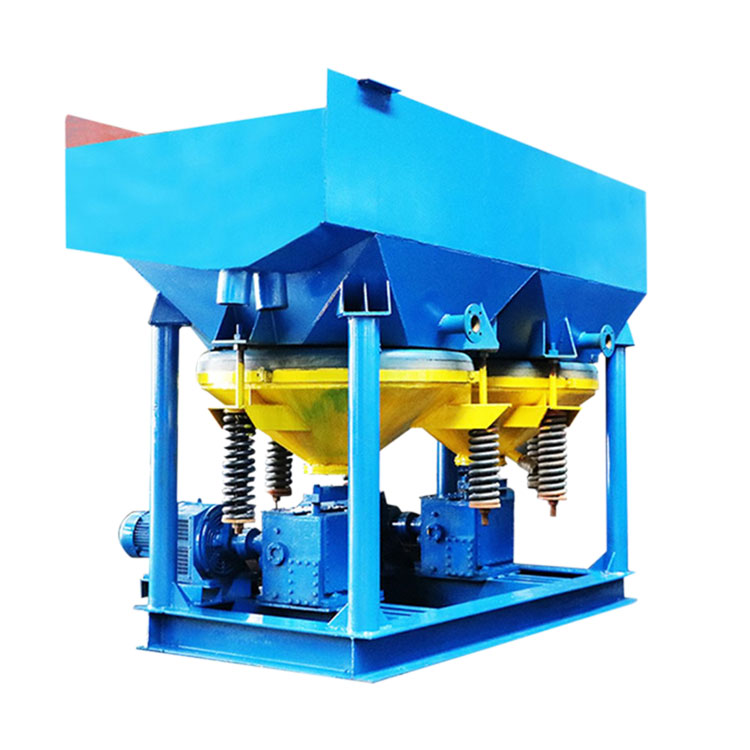

The sawtooth wave jig is a highly efficient gravity separation device designed for the beneficiation of coarse and medium-grained minerals based on density differences. It primarily consists of a jigging chamber, a drive system, a screen plate, and a discharge control mechanism. The drive system generates a unique sawtooth-shaped waveform—characterized by a rapid upward stroke followed by a slow, controlled downward pulse—through an eccentric drive or hydraulic mechanism. This specific wave profile enhances bed fluidization and particle stratification, allowing heavier particles to settle faster and more accurately than conventional jigs.

The jig features a flexible screen plate and an automated discharge system that continuously removes concentrated heavy minerals. Its sawtooth wave pattern ensures improved separation efficiency, higher recovery rates, and better adaptability to a wide range of particle sizes. With adjustable stroke length, frequency, and water flow, the jig offers precise process control and stable operation. It is widely used in medium- to large-scale mining operations for its high capacity and reliability.

Sawtooth Wave Jig Advantages

High separation precision for fine particles, effective enrichment of target minerals, and strong adaptability to varying feed grades.

Simple structure, easy installation and operation, low maintenance costs, and minimal power requirements.

Suitable for beneficiation of minerals such as gold, tungsten, tin, tantalum, iron, and chromite, as well as industrial minerals like silica sand and coal.

Ideal for processing gold, tin, tungsten, barite, manganese, hematite, and other alluvial or hard rock mineral resources.

Sawtooth Wave Jig Picture

Sawtooth Wave Jig Main Technical Parameters

Model | Area | Frequenty Stroke | Feed size | Make-up water | Water Pressure | Capacity | Power | Boundary dimensions |

㎡ | r/min | mm | m³/t | Mpa | t/h | kw | mm | |

JT0.57-1 | 0.57 | 80-180 | 0-6 | 1-2 | ≥0.05 | 1.5-3 | 1.5 | 1550*780*1530 |

JT1-1 | 1.04 | 80-180 | 0-10 | 2-3 | 2.5-5 | 2.2 | 2270*1110*1890 | |

JT2-2 | 2.28 | 80-180 | 0-10 | 2-4 | 5-10 | 3 | 3225*1550*2050 | |

JT3-1 | 3 | 50-125 | 0-10 | 3-6 | 7.5-15 | 5.5 | 2745*2000*3030 | |

JT4-2 | 4 | 50-125 | 0-25 | 4-8 | 8-20 | 7.5 | 4240*1990*2750 | |

JT4-2A | 4 | 50-125 | 0-25 | 4-8 | 8-20 | 4*2 | 4240*1990*2750 | |

JT5-2 | 4.86 | 80-120 | 0-10 | 3-6 | 12-25 | 7.5 | 3600*2000*2600 |

Send Inquiry