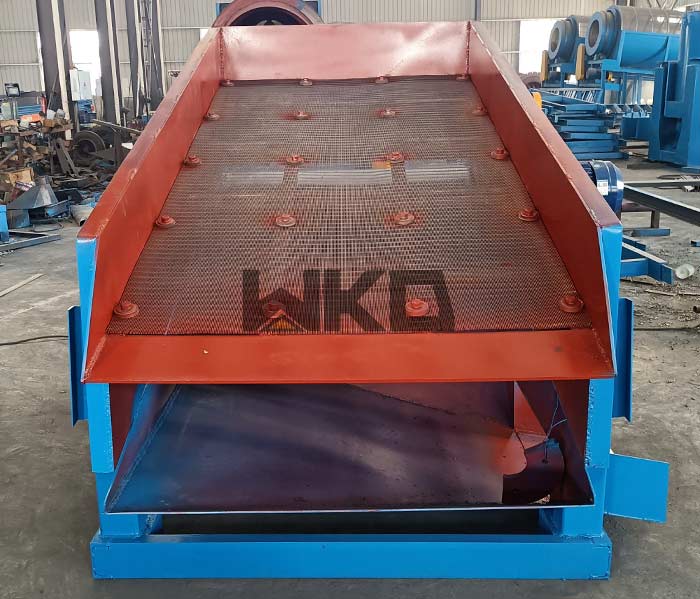

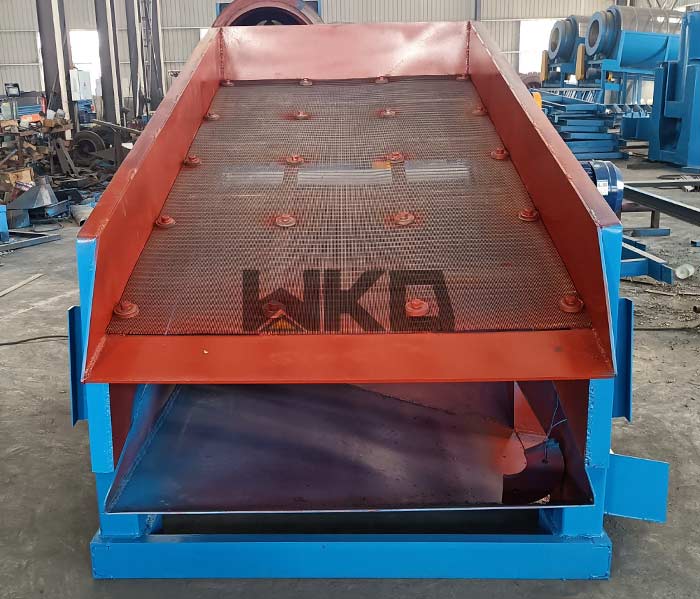

Circular Vibrating Screen

The vibrating screen utilizes vibrating motors as the excitation source to propel materials on the screen surface

Vibrating Screen Product Description

The vibrating screen utilizes vibrating motors as the excitation source to propel materials on the screen surface, causing them to be thrown upward while moving linearly forward. Materials are evenly fed into the screen's inlet via a feeder and are separated into several specifications of oversize and undersize particles through multi-layer screens. These separated materials are discharged from their respective outlets. With characteristics such as low energy consumption, high throughput, simple structure, easy maintenance, and automatic discharge, it is suitable for various mineral processing production lines.

Vibrating Screen Advantages

1.Low energy consumption, high production capacity, simple structure, and easy maintenance. 2.Automatic discharge functionality, adaptable to diverse mineral processing workflows. 3.Stable operation, low noise, and long service life.

Vibrating Screen Picture

Vibrating Screen Main Technical Parameters

Model | Layer | Max Feeding size (mm) | Sieve size (mm) | Capacity (t/h) | Frequency (r/min) | Angle(°) | Motor Power (Kw) | Dimension L*W*H | Weight (kg) |

SZZ600×1200 | 1 | 40 | 1-25 | 10-20 | 1000 | 15-25 | 2.2 | 1370×890×330 | 340 |

SZZ2600×1200 | 2 | 40 | 1-25 | 10-20 | 1000 | 15-25 | 2.2 | 1370×890×430 | 360 |

SZZ900×1800 | 1 | 40 | 1-25 | 20-25 | 1000 | 15-25 | 2.2 | 2150×1358×575 | 550 |

SZZ2900×1800 | 2 | 40 | 1-25 | 20-30 | 1000 | 15-25 | 3 | 2489×1358×770 | 620 |

SZZ1250×2500 | 1 | 100 | 5-40 | 150 | 850 | 15-20 | 5.5 | 2762×1714×680 | 1100 |

SZZ21250×2500 | 2 | 150 | 5-40 | 150 | 850 | 15-20 | 5.5 | 2702×1714×740 | 1300 |

SZZ1500×3000 | 1 | 100 | 1-40 | 220 | 800 | 15-25 | 7.5 | 3320×1449×787 | 2100 |

Send Inquiry